About Us

Stock Is Not An Option

America's Premiere Remanufactured Diesel Engine Facility.

The Choate Story

At Choate Engineering Performance, we were born out of a necessity for accountability. For years, we saw machine shops "let go of the rope"—failing to take responsibility for precision and quality. We made a choice: either quit, or become the best machine shop in the country.

We chose the latter. Today, we own every step of the process. When we build an engine, we are holding the rope for you, ensuring your vehicle stays on the road longer than the day it left the showroom.

Our Expertise

Automotive Division

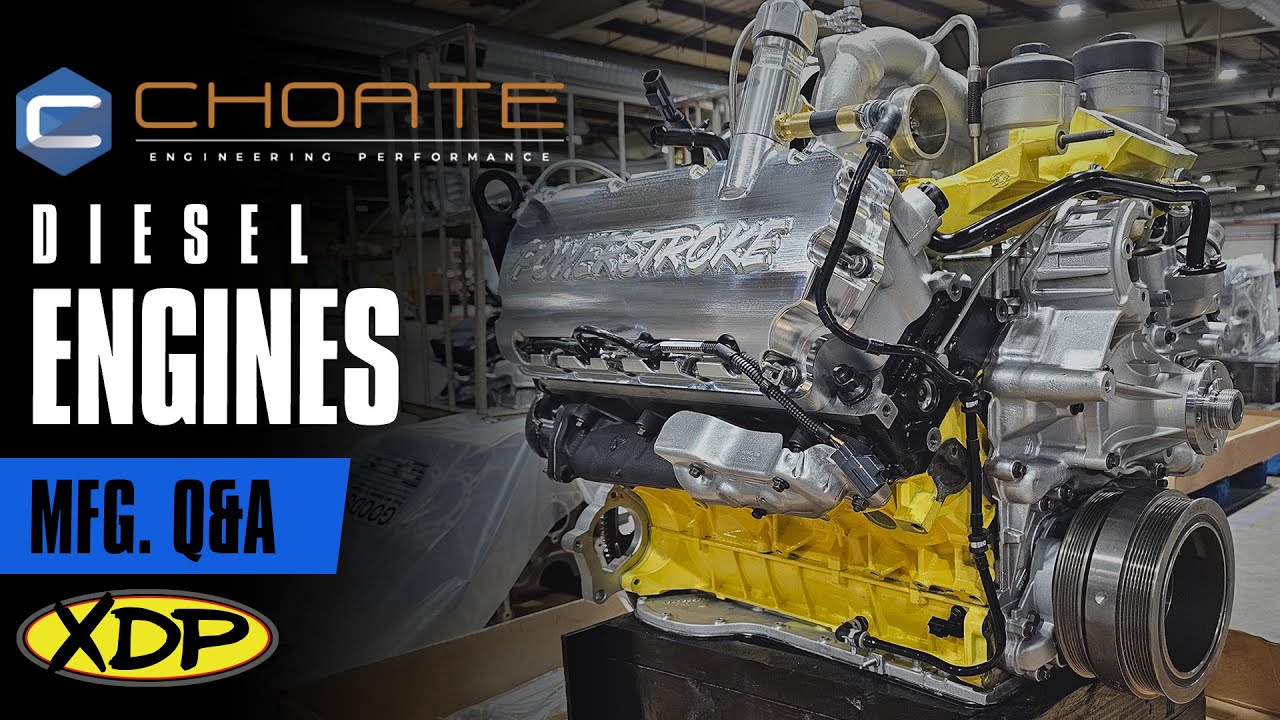

Our Automotive Division is dedicated to the heartbeat of the American roadway: diesel trucks. We specialize in high-performance remanufacturing for Powerstroke, Cummins, and Duramax platforms, moving far beyond simple repairs to provide total engine rebirths. By utilizing in-house CNC machining and precision balancing, we eliminate notorious factory weak points—such as cracked pistons and crankshaft failures—ensuring your truck delivers superior reliability whether it’s a daily driver, a dedicated tow rig, or a high-performance build.

Industrial Division

The Choate Industrial Division understands that in sectors like construction, forestry, and oil and gas, downtime is the enemy of profitability. We specialize in the high-precision remanufacture of heavy-duty platforms, including industry staples like Caterpillar and Detroit Diesel. Whether you are operating earthmoving equipment, stationary power plants, or large-scale agricultural machinery, our engines are re-engineered to withstand the harshest environments.

Marine Division

In the Marine Division, we recognize that engine failure isn't just an inconvenience—it’s a safety concern. We remanufacture marine diesel engines to withstand the unique stresses of aquatic environments, including constant high-load cycles and corrosive conditions. By applying our signature 4- and 5-axis machining precision to marine blocks and heads, we provide boat owners and commercial operators with a power plant that offers smoother operation, better fuel efficiency, and the peace of mind that comes with a Choate-certified build.

Technical Capabilities

Understanding the critical difference between a remanufactured diesel engine and a standard "rebuilt" unit is the first step toward ensuring the longevity of your vehicle. While a rebuilt engine is often a mere "patch job" where a technician simply tears down the block to replace only what is broken, a Choate Remanufactured Engine represents a complete engineering rebirth. We strip every engine to its core for thermal cleaning and utilize a precision machining process, meeting or exceeding original factory specifications. Rather than just replacing parts, we proactively upgrade the design to solve known factory defects, ensuring our engines are built better than new. For the educated consumer, the choice is clear: don't settle for a repair when you can invest in a high-performance diesel engine redesigned for ultimate durability and a second life on the road.

At Choate Engineering Performance, we believe that the heart of a high-performance diesel engine lies in the precision of its internal geometry, which is why we specialize in truly balanced rotational assemblies. Unlike mass-production facilities that rely on "stack tolerances" or factory-acceptable margins, we treat every crankshaft, rod, and piston as a single, cohesive unit. By utilizing state-of-the-art balancing equipment, we eliminate the harmonic vibrations that lead to premature bearing failure and engine fatigue. This meticulous attention to detail ensures that your engine doesn't just run—it operates with a level of smoothness and efficiency that reduces internal friction, maximizes horsepower, and significantly extends the life of the engine. Whether you are hauling heavy loads OTR or pushing limits in the field, our balanced assemblies provide the mechanical stability required for the most demanding environments.

At Choate Engineering Performance, we believe that true quality control can only be guaranteed when every critical process happens under our own roof. Our facility is equipped with advanced 4- and 5-axis CNC machining centers, flow benches, and precision testing equipment, allowing us to handle every stage of the remanufacturing process in-house. By keeping these specialized services on-site, we eliminate the risks associated with third-party outsourcing and ensure that every component is machined to our exacting tolerances. This hands-on approach gives us the total confidence that every engine shipping across the country has been scrutinized, tested, and verified to meet the highest level of mechanical integrity.

The Choate standard is defined by engineering out the weaknesses that the original manufacturers left behind. Every remanufactured diesel engine we produce is a "re-engineered" powerhouse, designed to solve notorious OEM design flaws that lead to catastrophic failures. From correcting cracked pistons in the Powerstroke 6.4L and bearing failures in the Cummins 6.7L to addressing broken Duramax crankshafts and frequent valve seat issues, we don’t just replace parts—we improve the platform. By combining precision balancing technology with upgraded component designs, we deliver an engine that is more reliable, more durable, and more efficient than the day it first rolled off the factory assembly line.

At Choate, we prioritize quality over quantity by choosing to focus on the precision of every individual build rather than the high-volume output of mass-production factories. We aren't interested in churning out hundreds of thousands of generic engines; instead, we invest the extra time required to do the job right, providing our customers with long-term savings through unmatched reliability and higher-grade components. By refusing to cut corners, we ensure your equipment stays in the field and out of the shop. Whether you are in forestry, construction, marine, oil and gas, stationary power, material handling, transportation, OTR, rail, fleet, or agriculture, let the Choate standard repower your business with an engine built to endure.

Featured By: The Industry Experts

"Over the past decade, Choate has made a name for itself taking factory diesel engines... and re-building them to run longer and perform better than when they first rolled off the factory floor."

"They are building engines with more options as standard equipment than any of their competitors... excellence is their standard."

"Learn where corners are cut in OEM reman engines and how Choate engineers those problems out of existence."

"Cass and the guys discuss how Choate rose to such prominence in the diesel community by solving Powerstroke issues that others simply ignored."

"Cass Choate has built a business on creating aftermarket solutions for OEM diesel problems... leading the way in engineering permanent fixes."

"If you’re thinking about a crate engine for your truck... this covers the history and innovation behind Choate’s success."

- Choosing a selection results in a full page refresh.